THERMAL TARGETS

IntelliParticle has developed an innovative range of large-scale tank and armored vehicle thermal targets designed to enhance live training for target acquisition. Utilising our patented conductive HeatPaint technology, these targets quickly register thermal signatures, making them ideal for live-fire exercises.

Our HeatPaint technology represents a significant advancement in thermal target training and defense applications. Our solutions offer realistic, durable, and cost-effective thermal signatures for a variety of training and operational needs. We invite you to explore the possibilities our technology offers and look forward to collaborating with you to enhance your training capabilities.

Thermal Targets

www.thermaltargets.com.au

Call +61 411550652

Patented HeatPaint Technology

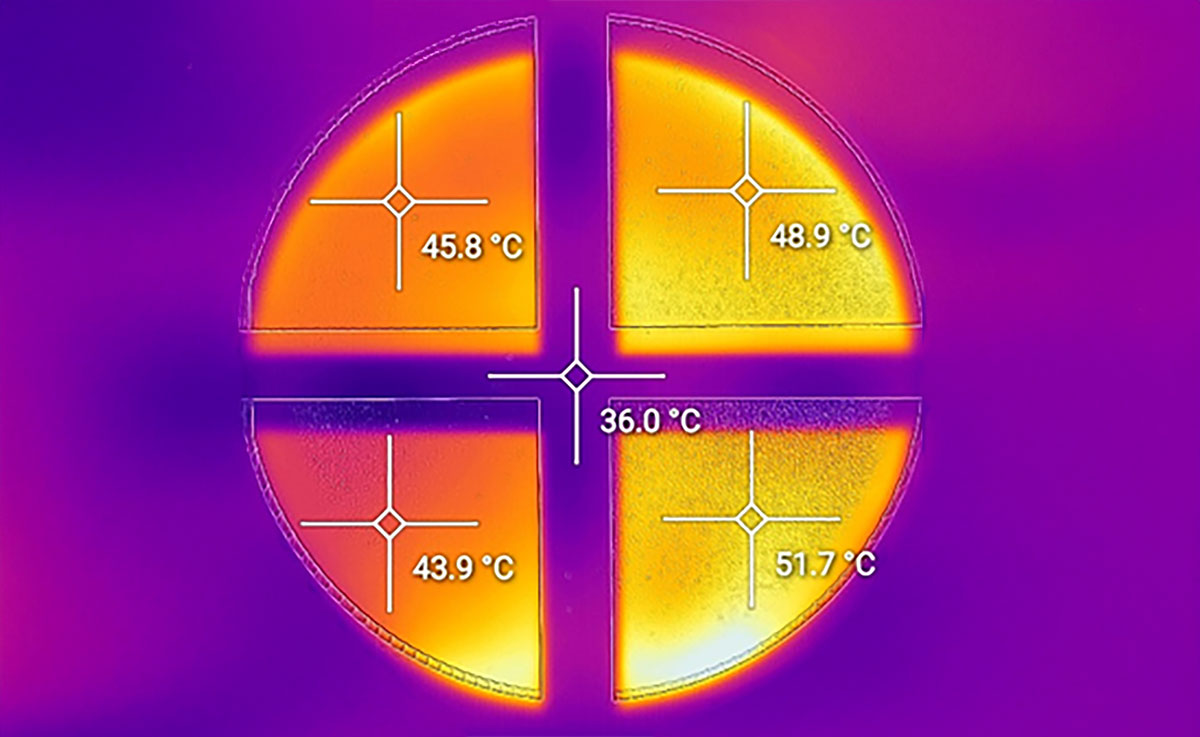

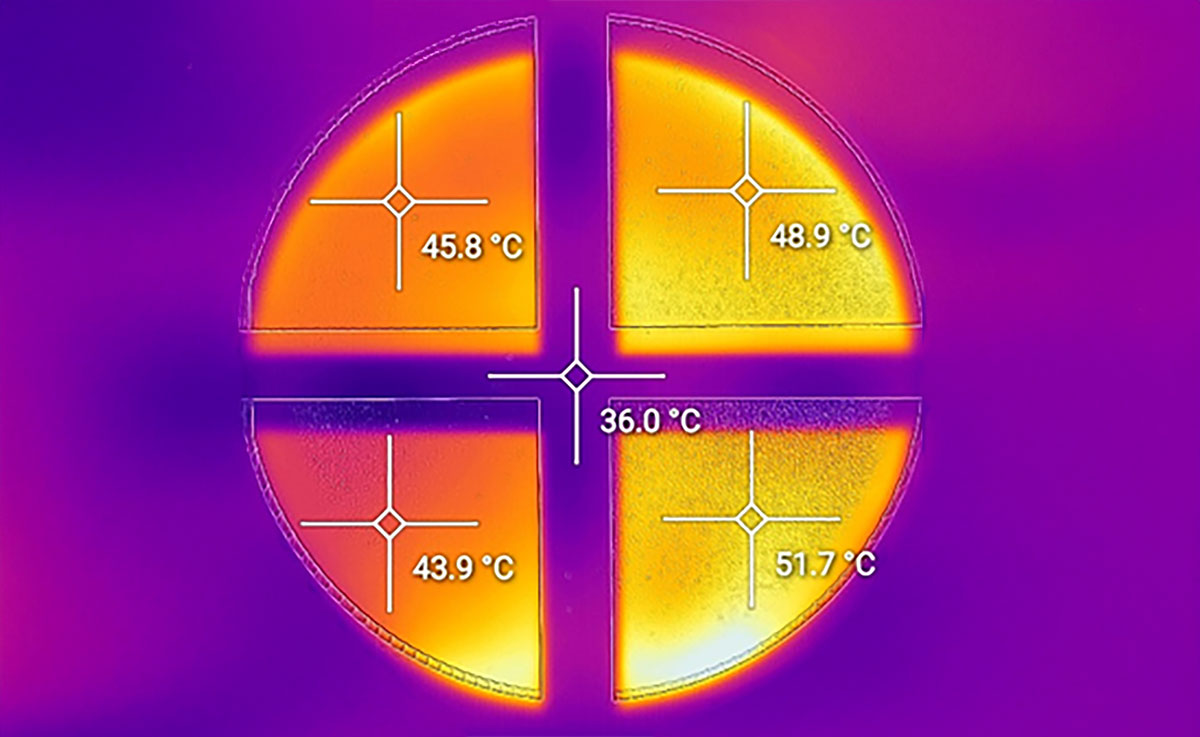

At the core of our solution is a patented conductive acrylic paint that can be applied to any non-conductive surface such as plywood or corflute. When connected to a low-voltage power source (as low as 9V, 12V, or 24V), the paint heats up, producing a controllable thermal signature detectable by thermal scopes and sensors. Our HeatPaint achieves temperatures ranging from 26°C to over 100°C, with fast heat-up rates of 5–10 seconds and rapid cool-down.

- Low Voltage Operation: Targets are battery operated, making them suitable for remote locations.

- Durable and Reliable: Targets can be shot multiple times and will continue to function as long as the electrode remains intact.

- Safe and Stable: The paint has a near-zero Temperature Coefficient of Resistance (TCR), preventing thermal runaway and ensuring consistent operation.

Advantages Over Existing Solutions

Unlike traditional thermal targets that rely on passive heat reflection (e.g., reflective tape or black-and-white designs) or primitive methods (e.g., hot coals, electric blankets), our HeatPaint targets offer:

- Active Thermal Signatures: Emit heat actively for more realistic and detectable thermal profiles.

- Cost-Effectiveness: Provide an economical “throw-away” solution suitable for live-fire training where targets are destroyed.

- Customisability: Can be designed to any size or shape to meet specific training requirements.

- Integration Capability: Can be integrated with existing target systems or operate as standalone products.

Cable Options for Thermal Targets

Target Types

We have developed two distinct product lines in collaboration with military units:

- Small Arms and Sniper Targets: Ideal for calibrating scopes and live training with both pop-up and fixed structures.

- Large Targets for Tanks and Armored Vehicles: Suitable for live-fire exercises, measuring up to 1.2m x 2.4m, assisting tank crews in spotting enemy shapes during training exercises at ranges up to 5 kilometers.

Easy Deployment and Customisation

Creating a thermal target with our HeatPaint technology can be accomplished in as little as 15 minutes:

- Select a Non-Conductive Substrate: Common materials include plywood and corflute.

- Apply Electrodes: Place self-adhesive copper electrodes on the left and right sides to create the heating element.

- Apply HeatPaint: Paint the area between the electrodes with our conductive paint, which serves as the resistor and heats up when powered.

- Dry the Paint: Use a heat gun on a low setting to expedite drying.

- Test Resistance: Use a multimeter to ensure the ideal resistance (approximately 5 ohms for 12V power sources). Apply additional coats if necessary to adjust resistance.

- Connect Power Source: Plug into a power source and adjust to achieve the required thermal signature.

Definition of Target

A remarkable definition of target is possible as the facia is distanced from the heated rear panel via the white 8mm corflute. So, two distinct heat signatures are registered by the thermal scope at over 200m. Also, the contrast from the reflective white facia and the deep black used to create our paint means the target can be used an excellent passive target.

Integration and Compatibility

Our HeatPaint targets can be integrated with existing target field systems or operated as standalone units. They are compatible with low-voltage power supplies, making them suitable for remote locations where power resources may be limited. Our team has vast experience designing solutions quickly and economically for different environments, including high humidity, tropical, and wet weather conditions, with options for waterproofing and encapsulation.

Unique Thermal Signatures and Countermeasures

Our technology allows for the creation of custom heat signatures by adjusting paint thickness and power input. This enables us to replicate specific thermal profiles, such as:

- Vehicle Components: Mimic the varying temperatures of a truck wheel’s axle and tire body.

- Equipment Decoys: Simulate heat signatures of generators, personnel, or gas burners to serve as decoys against guided ordnance.

- Comprehensive Decoy Sites: Create entire thermal bivouacs using simple materials like plywood, presenting as accurate thermal targets.

Such precision makes our targets effective for testing missile guidance systems and developing thermal countermeasure strategies. Wire technology cannot match the cost-effectiveness or the discreetness of our painted targets.

Thermal Targets

www.thermaltargets.com.au

Call +61 411550652

Additional Defense Applications

Beyond thermal targets, our HeatPaint technology has potential applications in various defense scenarios:

- Emergency Medical Warmth: Provide heat in remote or harsh environments.

- Food Warming Solutions: Develop low-voltage heating elements for field kitchens.

- Aerial Decoy Campsites: Simulate heat signatures of campsites or personnel to mislead enemy surveillance.

- Low-Voltage Cooktops: Create portable cooktops capable of reaching temperatures of 120°C with 14V and 3A.

- Equipment in Cold Environments: Maintain optimal operating temperatures for equipment and communication batteries in sub-zero conditions.

- Heated Clothing Panels: Integrate heating elements into clothing for personnel operating in cold climates.

Our heating elements are a solution to these uses and can be created on any non-conductive surface.

Product Trials and Next Steps

We believe our HeatPaint technology speaks for itself. We are willing to provide finished target products and samples of our paint for you to experiment with and evaluate its effectiveness in your training programs.

Patent Information

Our HeatPaint technology is protected under a USA/world patent. The core innovation lies in its Temperature Coefficient of Resistance (TCR) of approximately zero. This means that the resistance of our carbon/graphite formulation remains stable under electrical current, preventing thermal runaway and ensuring safe, consistent operation without the risk of combustion.